Cooling From a Different Angle

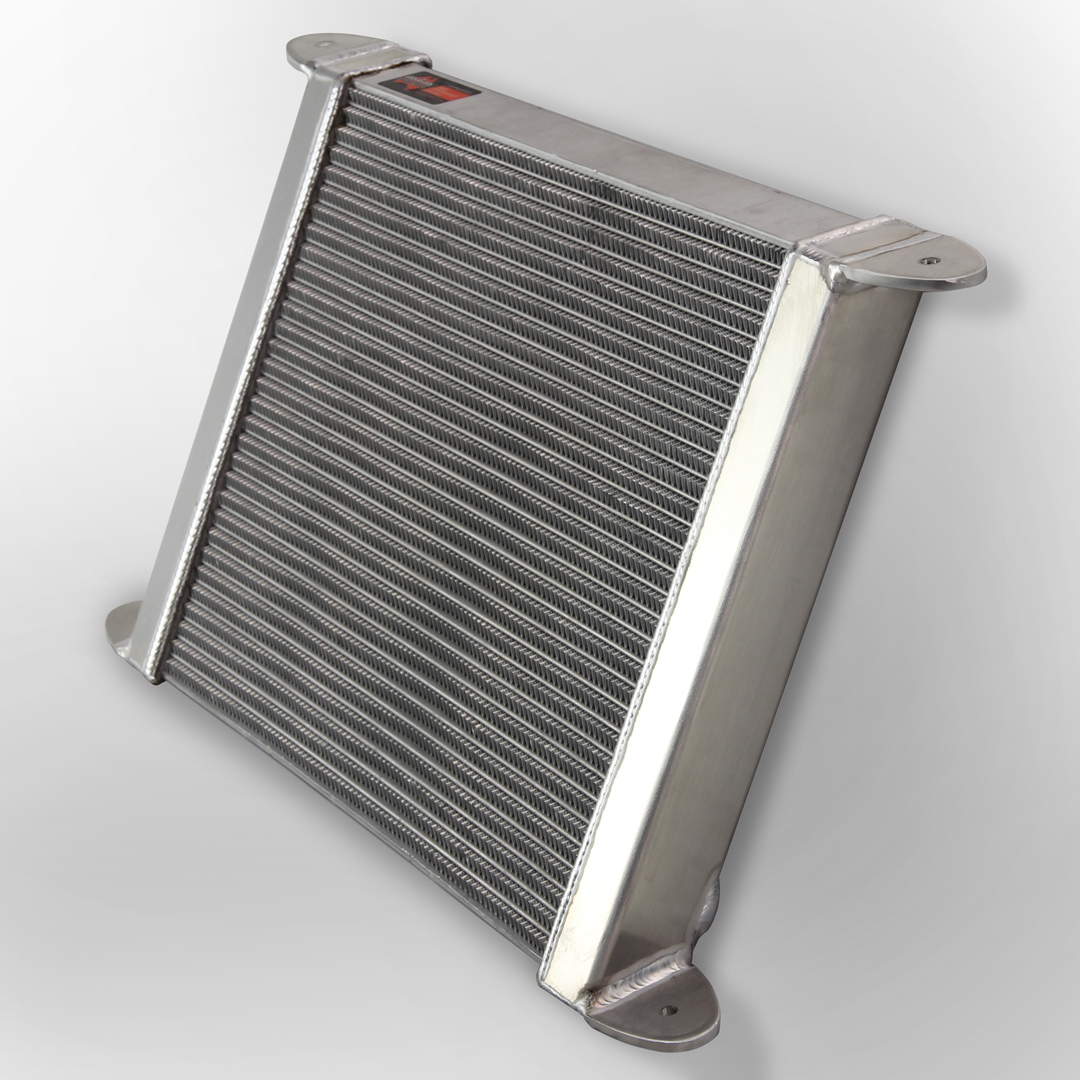

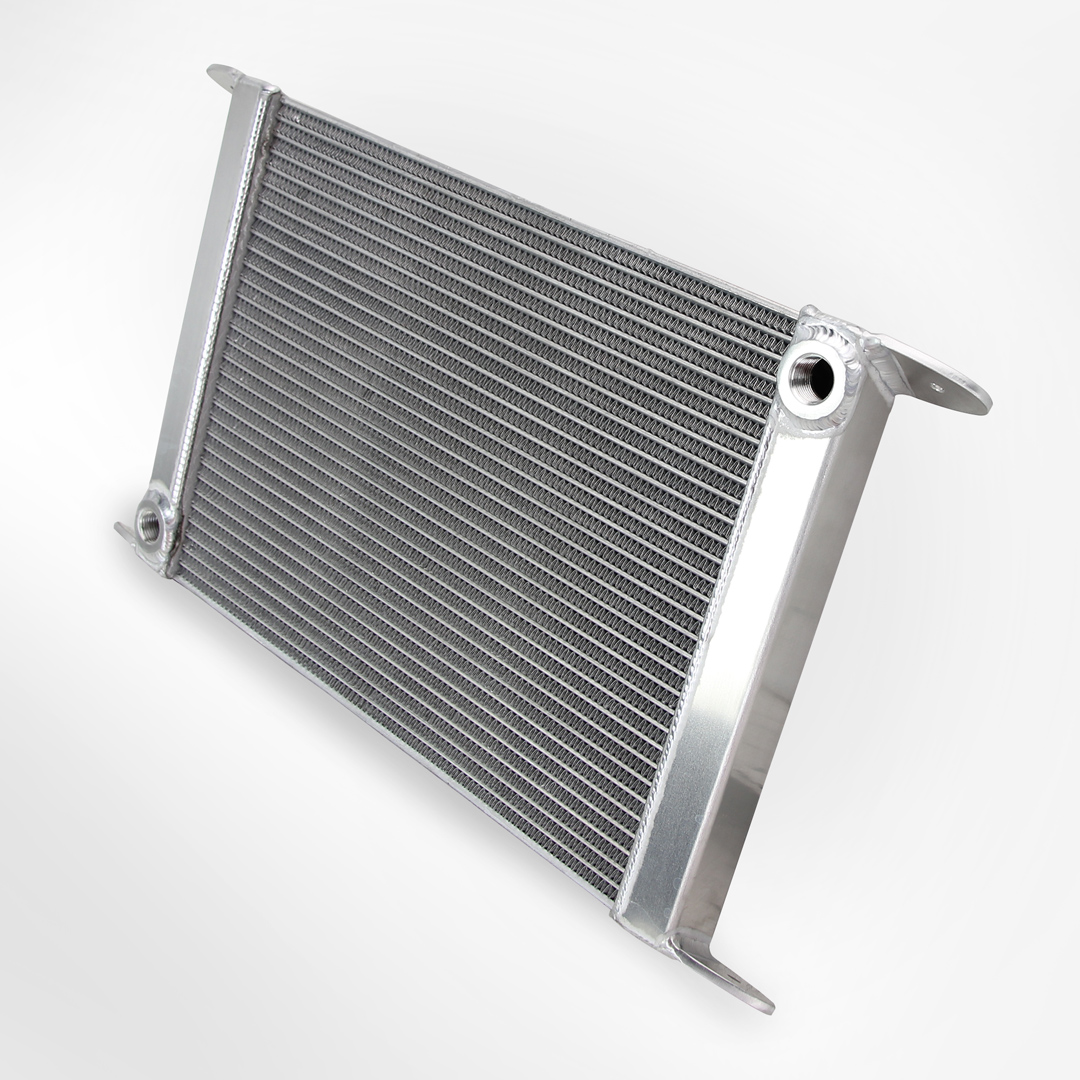

Here's an example of a specialty radiator manufactured at Adrad's Adelaide performance alloy manufacturing facility. It features Adrad's unique 4.75mm high XF fin to fit as many water tubes as possible in the limited height available to achieve maximum cooling performance

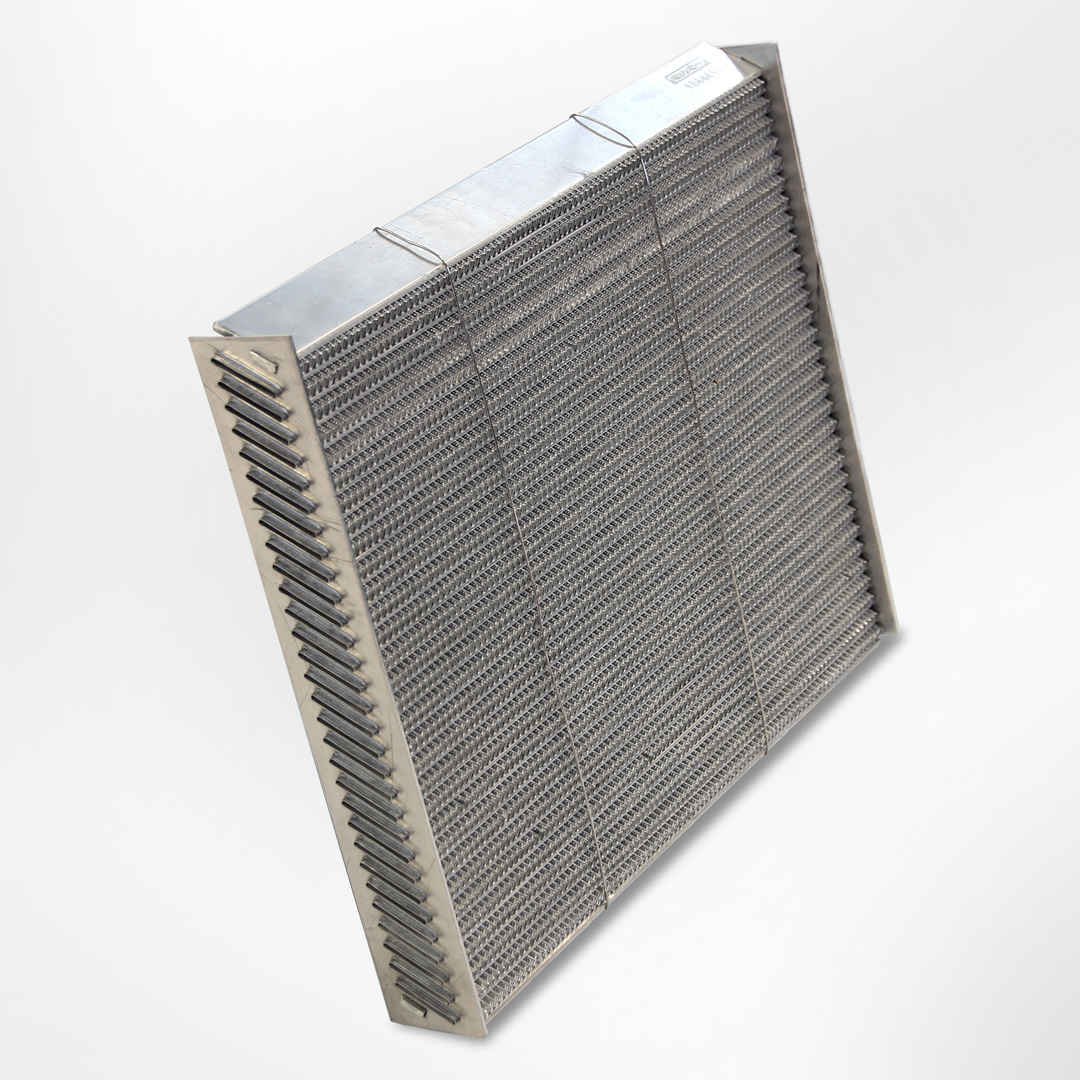

The stepped core design allows the radiator to be angled for a more compact height, without compromising air flow, minimising pressure drop, vital for drawing heat away from the radiator for more effective cooling.

As shown in the diagram below, tilting a conventional radiator compromises cooling performance as air cannot effectively flow through the core.

This bespoke radiator is assembled and precision welded by hand, then pressure tested to make sure it performs faultessly, even under the most extreme condiitons

CONNECT WITH

Recent Posts

Lincoln Welder

Nov 12, 2020 Read More

Off-Road Racing Radiator

Nov 10, 2020 Read More

Adrad Performance Bathurst

Oct 23, 2020 Read More

Dana Available from Adrad Performance

Jul 7, 2020 Read More

Universal Shroud & Fan Kits

Nov 28, 2019 Read More

S5000 Race Cars Cooled by Adrad

Nov 19, 2019 Read More

Custom Made Alloy Radiator for BMW K100

May 16, 2019 Read More

Adrad Are At MotorEx 2019

May 9, 2019 Read More

Adrad Delivers Performance Cooling for a 2009 RC Colorado 3.0L Turbo Diesel

May 6, 2019 Read More

John's 2019 Dakar Rally Race Report

Feb 19, 2019 Read More

Cool Bus

Feb 12, 2019 Read More

Stepping Up Your Cooling Performance

Nov 20, 2018 Read More

QUESTIONS? CALL US : 1800 069 610

OR CLICK HERE TO : ENQUIRE ONLINE

LATEST NEWS & DEALS

SIGN UP NOW FOR THE LATEST NEWS AND GREAT DEALS

THINGS YOU NEED TO KNOW

Before you buy, please read the Performance Parts Trading, Warranty & Claims and Terms & Conditions.

Having Trouble Fitting your radiator read the ADRAD Radiator Warranty and Installation Guide.

News

Lincoln Welder

Custom built alloy radiator for welding machine. Another Adrad Performance...

Read More